Tower Singapore

08:00 - 20:00

Schaeffler at the InnoTrans 2018

The railway industry was in a mood of optimism and change at InnoTrans 2018 and Schaeffler is playing an active role in shaping this mobility. During the four-day event, Schaeffler presented and discussed bearing supports with increased performance for drive systems and wheelsets and innovative service concepts. We have compiled the highlights for you.

to the review

The mobility of tomorrow must be more sustainable, more efficient, quieter, and safer. Schaeffler is making a decisive contribution here, and has established itself as a central development partner in the field of rolling bearing solutions for rail traffic applications.

The expertise and comprehensive technical knowledge of the specialists in Schaeffler's Railway Sector Management are in demand in a wide range of projects, including high-speed transportation, freight transportation, and local transport in the world's growing megacities.

Applications & Products

Pulled cars and multiple units

With more than 100 years of experience in the railway sector, Schaeffler is a reliable partner that delivers comprehensive technical expertise and the highest possible levels of quality to its customers. Perfectly matched solutions for every bearing application in rail vehicles are created in close collaboration with manufacturers and operators.

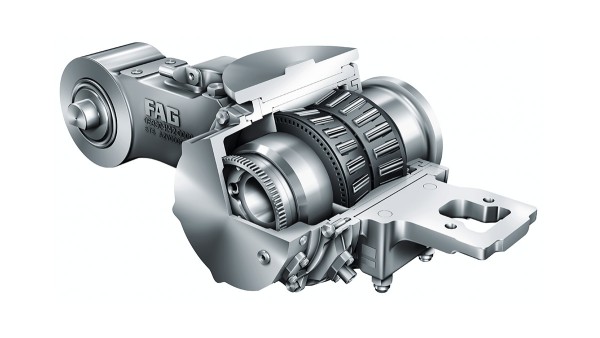

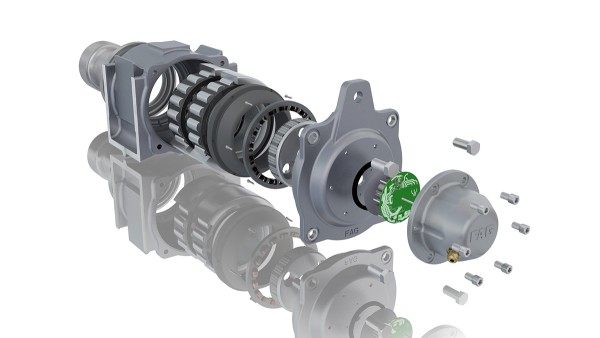

Traction motors & gearbox bearings

Rolling bearings from Schaeffler make an important contribution to increasing traveling comfort and cost-effectiveness and to reducing noise emissions in gearboxes, traction motors, and suspension tubes.

Axlebox bearings for freight cars

Axlebox bearings from Schaeffler also prove themselves in freight cars, even under demanding environmental conditions, thanks to their long operating life and low maintenance outlay.

Axlebox bearings for passenger cars & locomotives

The rolling and plain bearings that Schaeffler develops and manufactures for chassis, bogies, and their components ensure reliability, safety, and comfort.

Mechatronics

Schaeffler is systematically expanding its mechanical components to create mechatronic modules that offer significant additional benefits in freight and passenger transportation.

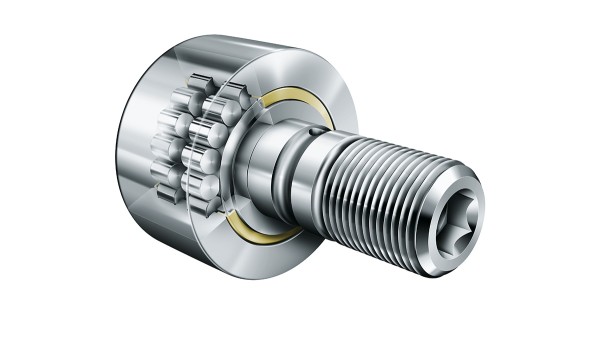

Other bearing supports

Bearings from Schaeffler are also ideal for use in overhead wire tensioning pulleys and points, tilting technology and stabilizing systems, and track gauge adjustment systems thanks to their robustness, reliability, and high cost efficiency. They also ensure safety and a long operating life in bearing supports for door systems and boarding aids, for railcar body and bogie connections, and for braking systems.

Service

Railway testing facility, validation & bearing reconditioning

Over the last few years, Schaeffler has established itself as a major partner for the development of rolling bearing solutions for freight and passenger traffic, for high-speed trains, and for locomotives.