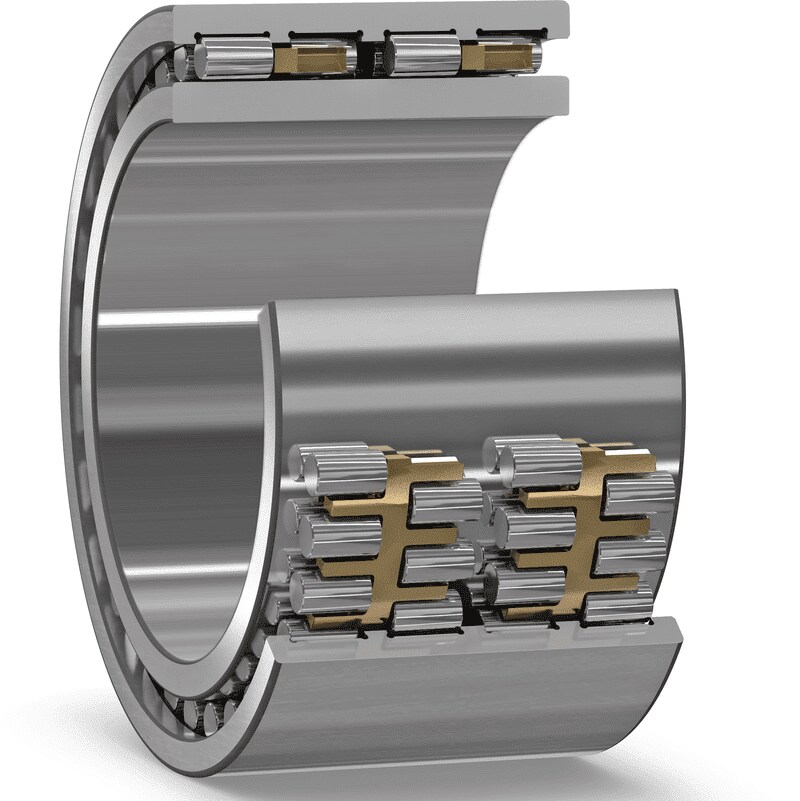

Cylindrical roller bearings

_131_0_685_555.jpg)

the number of roller rows (one, two or four)

the type of cage (with, without or special designs)

Bearings with a cage can accommodate heavy radial loads, rapid accelerations and high speeds.

Full complement bearings (without a cage) incorporate a maximum number of rollers and are therefore suitable for very heavy radial loads at moderate speeds.

SKF high-capacity cylindrical roller bearings combine the high load carrying capacity of a full complement bearing with the high speed capability of a bearing with cage.

the configuration of the inner and outer ring flanges (position and number of guide flanges)

Bearing features

High load carrying capacity

High stiffness

Accommodate axial displacement (fig. 1)

Except for bearings with flanges on both the inner and outer rings.

Low friction

The open flange design (fig. 2), together with the roller end design and surface finish, promote lubricant film formation resulting in lower friction and higher axial load carrying capacity.

Long service life

The logarithmic roller profile reduces edge stresses at the roller/raceway contact (fig. 3) and sensitivity to misalignment and shaft deflection.

Enhanced operational reliability

The surface finish on the contact surfaces of the rollers and raceways supports the formation of a hydrodynamic lubricant film.

Separable and interchangeable

The separable components of SKF cylindrical roller bearings are interchangeable (fig. 4). This facilitates mounting and dismounting, as well as maintenance inspections.

Bearings with Solid Oil

INSOCOAT bearings

Hybrid bearings

NoWear coated bearings

Super-precision bearings

Backing bearings

Indexing roller units

Cylindrical roller bearings and bearing units for railway applications (→ contact SKF)

_131_0_685_555.jpg)

_0_0_800_801.jpg)

_147_5_693_552.jpg)