Slewing bearings

Bearing features

Depending on their design, slewing bearings have the following features:

High load carrying capacity

High stiffness for rigid bearing application

Low friction

Long service life

Surface protection and corrosion resistance

Integration of additional features, including:

driving mechanism

control devices

lubrication systems

monitoring systems

sealing cassettes

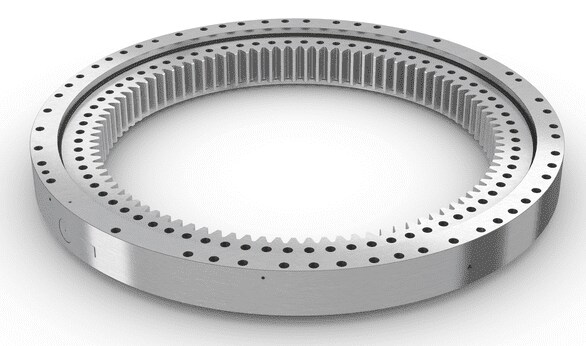

Designs

SKF manufactures standard and customized slewing bearings in various designs with outside diameters from 0,1 to 18 m to meet the demands of particular applications. The most common designs are:

Four-point contact ball bearings (fig. 1)

Optimal economy and capacity for given dimensions or when replacing existing multi-bearing arrangements

Eight-point contact ball bearings (fig. 2)

80% increase in capacity compared to a same-sized single-row four-point contact ball bearings

Crossed cylindrical roller bearings (fig. 3)

High stiffness and constant resistance to rotation

Triple row roller bearings (fig. 4)

Provide highest capacity for a given diameter

Wire race bearings (fig. 5 and fig. 6)

60% lighter compared to same-sized all-steel bearings

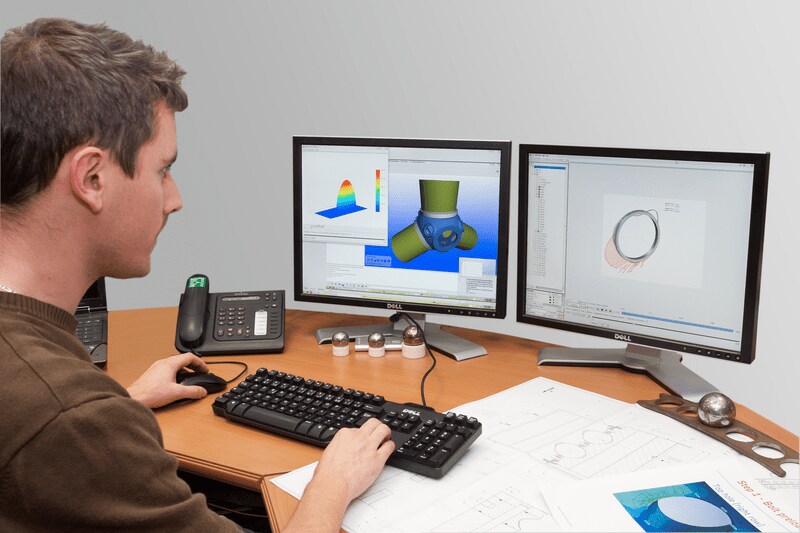

SKF has extensive experience in designing and manufacturing customized or special slewing bearings. Examples are:

Combined roller/ball bearings (fig. 7)

Segmented bearings

Inserted raceways bearings

Applications

SKF offers high-performance slewing bearings for a wide range of applications, including:

Wind turbines

Tunnel boring machines

Excavators

Forestry vehicles

Rail vehicles

Dockside and deck cranes

Mobile cranes

Water treatment equipment

Bottle filling systems

Metals

Material handling

Marine pods

Offshore buoys

Stacker reclaimers

Surveillance systems (e.g. radars, cameras)

Medical equipment

Tidal turbines