SH bushings

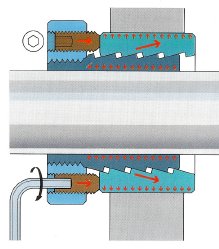

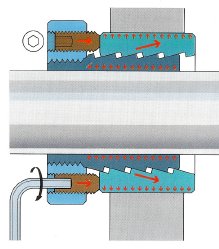

The inner and outer components of the SH bushing are threaded to correspond to a divided taper angle. A nut with screws is fitted to the inner component. When the screws are tightened, the outer component is subject to axial pressure and “climbs” up the thread on the inner component. The slotted inner component will be pressed against the shaft and the outer component, if slotted, will be pressed against the hub (fig 1).

fig 1

Key joints can be dispensed with

With SH bushings there is no need to increase the shaft diameter and no need for lost time machining keyways and axially securing the joint.

The hub is there

Hub/shaft assemblies often need some form of intermediate hub. Either as an integral part of the hub proper or welded into it.

The SH bushing is made of weldable steel. With an un-slotted outer component (SHR), it can be welded directly into the hub bore.

It acts as an intermediate hub and saves time and material.

No need to worry about slip

The SH bushing is designed for heavy loads, for both torque and axial forces. Accurate finish machining and narrow tolerances for hub and shaft will always be needed, however. The SH-Bushing only needs a tolerance of h11-k6 on the shaft and H7-H11 in the hub.

Temperature can be ignored

The SH bushing is entirely mechanical. There are no temperature-sensitive hydraulic parts. So it can be used anywhere – even in extreme cold or heat.