Lubrication pumps and pumping units

Lubrication pumps feed lubricant from the lubricant reservoir into the tubing system of the centralized lubrication system. The manometric pressure has to be high enough to compensate for pressure drops in the tubing, components (filters, valves, distributors) and friction points.

Differentiation criteria:

type of lubrication system

principle of operation

type of drive

pump design

lubricant

lubricant quantities required by the system

pressure ranges temperature ranges

Piston pumps

Gear pumps

Gerotor pumps

Vane pumps

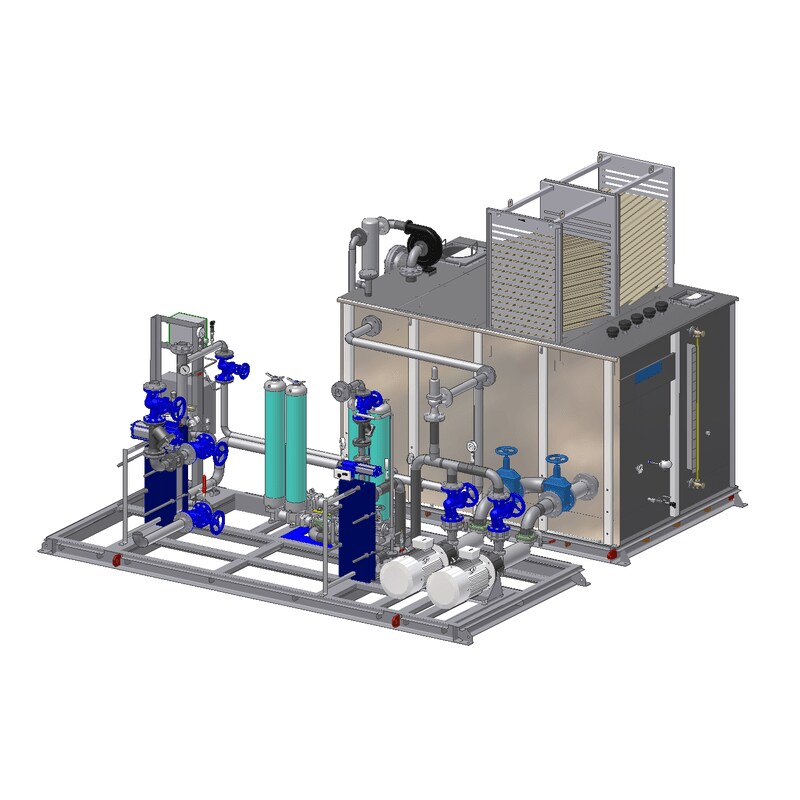

Oil circulating pump units

Overview of pumps and pump units for different lubrication systems

Single-line lubrication systems

| Product | Lubricant | Metering quantity | |

| Manually operated pumps / pump units | cm³/stroke | in³/stroke | |

| 1812 | oil grease NLGI 000, 00 |

2,6 | 0.16 |

| POE | oil | 15 | 0.9 |

| PFE |

oil grease NLGI 000, 00 |

15 | 0.9 |

| 83817 | grease NLGI 0, 1 , 2 | 1,6 | 0.09 |

| 1810 | grease NLGI 0, 1 , 2 | 2,6 | 0.16 |

| Air operated pumps/pump units | cm³/stroke |

in³/stroke | |

| 82885, 83667 | oil grease NLGI 000, 00 |

7,4 | 0.45 |

| 85438/40/41 | oil grease NLGI 000, 00 |

7,4 | 0.45 |

| P/PW/PF/PFW-289 | oil grease NLGI 000, 00 |

10 | 0.61 |

| POEP | oil | 15 | 0.9 |

| PFEP | grease NLGI 000, 00 | 15 | 0.9 |

| PPS30 | oil grease NLGI 000, 00 |

30 | 1.83 |

| 82676 | oil grease NLGI 000, 00 |

39,3 | 2.39 |

| 82570 | oil grease NLGI 000, 00 |

39,3 | 2.39 |

| 85430/31/32/33 | oil grease NLGI 000, 00 |

39,3 | 2.39 |

| PEF/PEU | oil grease NLGI 000, 00 |

48 | 2.93 |

| 40PGA | grease NLGI 0, 1, 2 | 40 | 2.44 |

| 82886, 83668 | grease NLGI 0, 1, 2 | 7,4 | 0.45 |

| 85442 | grease NLGI 0, 1, 2 | 7,4 | 0.45 |

| 85444/45 | grease NLGI 0, 1, 2 | 7,4 | 0.45 |

| 85434/35/36 | grease NLGI 0, 1, 2 | 18,7; 35,2 | 1.14; 2.15 |

| 82653/55 | grease NLGI 0, 1, 2 | 22,9 | 1.39 |

| 83800/34 | grease NLGI 0, 1, 2 | 35,2 | 2.15 |

| cm³/min | in³/min | ||

| 283167 | oil grease NLGI 000, 00 |

197 | 12.02 |

| 1826 | oil grease NLGI 000, 00 |

7571 | 462 |

| 83167 | grease NLGI 0, 1, 2 | 197 | 12 |

| 83599 | grease NLGI 0, 1, 2 | 197 | 12 |

| 84050, 85460 | grease NLGI 0, 1, 2 | 492 | 30 |

| 1827, 1828 | grease NLGI 0, 1, 2 | 2638 | 161 |

| 1829 | grease NLGI 0, 1, 2 | 3785 | 231 |

| Hydraulically operated pumps /pump units | cm³/stroke | in³/stroke | |

| HG 1000/2000 | grease NLGI 0, 1 | 0–1000/–2000 | 0–61.02/–122 |

| cm³/min | in³/min | ||

| 84944, 84961 | grease NLGI 0, 1, 2 | 180 | 11 |

| 84960, 84962 | grease NLGI 0, 1, 2 | 180 | 11 |

| FlowMaster | grease NLGI 0, 1, 2 | 15–737 | 7–45 |

| Electrically operated pumps | cm³/min | in³/min | |

| ECP | oil grease NLGI 000, 00 |

12 | 0.73 |

| P653S | oil grease NLGI 000, 00 grease NLGI 0, 1, 2 |

24,6 | 1.5 |

| KFB | oil grease NLGI 000, 00 |

50 | 3 |

| KFB-M | oil grease NLGI 000, 00 |

24,6 | 3 |

| KFU | oil grease NLGI 000, 00 |

140 | 8.5 |

| MKU | oil |

100; 200; 500 |

6; 12; 31 |

| MKF | oil grease NLGI 000, 00 |

100; 200; 500 | 6; 12; 31 |

| MFE | oil grease NLGI 000, 00 |

250; 500 | 15; 31 |

| P603S | grease NLGI 0, 1, 2 | 12 | 0.7 |

| Minilube | grease NLGI 0, 1, 2 | 13 | 0.8 |

| KFG | grease NLGI 0, 1, 2 | 15 | 0.9 |

| Multilube | grease NLGI 0, 1, 2 | 16 | 0.976 |

| FK | grease NLGI 0, 1, 2 | 74 | 4.5 |

| FlowMaster |

grease NLGI 0, 1, 2 | 103 | 6.3 |

Dual-line lubrication systems

Progressive lubrication systems