Minimal quantity lubrication systems

SKF LubriLean

System description:

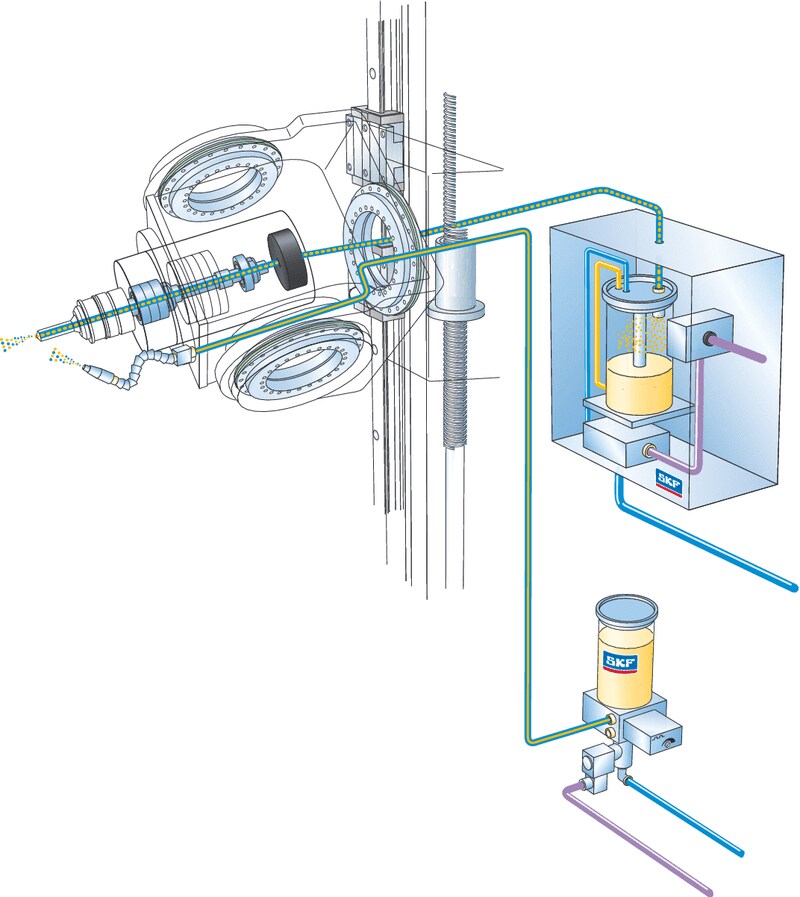

A minimal quantity lubrication system has the task of delivering minimal quantities of lubricant to the active site between the tool and work-piece when cutting or non-cutting operations are involved. Lubrication is performed by an aerosol that is formed by oil droplets that are finely dispersed in an air stream. Minimal quantity lubrication (MQL) can be fed to the tool or workpiece in two different ways, internal or external:

SKF LubriLean, internal MQL:

with the internal lubrication method, compressed air or the aerosol is applied through the spindle, the tool holder and the tool directly at the point between tool and workpiece.

SKF LubriLean, external MQL:

with the external lubrication method, the aerosol is supplied to the lubrication point from the outside through nozzles. With the right expertise, machine tools that are not supplied with internal MQL, can be upgraded with SKF LubriLean external method.

Applications:

Applications of SKF LubriLean for machine tools includes milling, rolling, cutting, drilling, boring, forming among others.

Discover SKF Minimal Quantity Lubrication Solutions

Components of a minimal quantity lubrication system

SKF BeyondZero

This offer is part of the SKF BeyondZero portfolio of products, services and solutions designed to help our customer reduce environmental impact. Learn more.

Related documents

SKF solutions for machining operations – BeyondZero portfolio

(1.9 MB)

Product brochure

(1.0 MB)

Market brochure: 15455 EN

(3.1 MB)