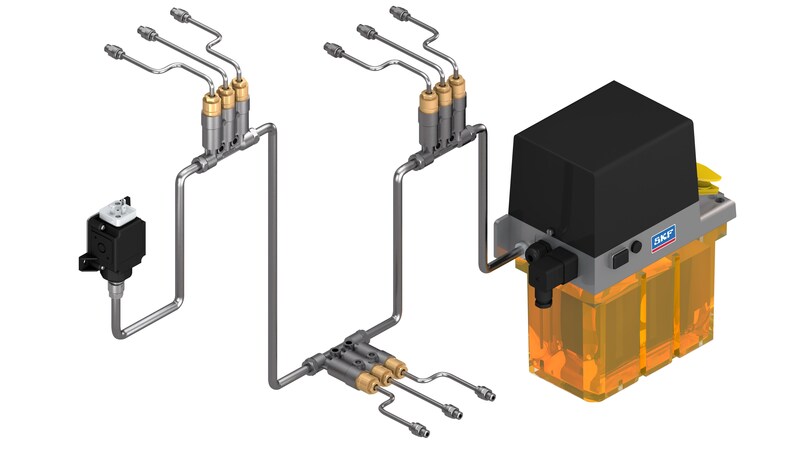

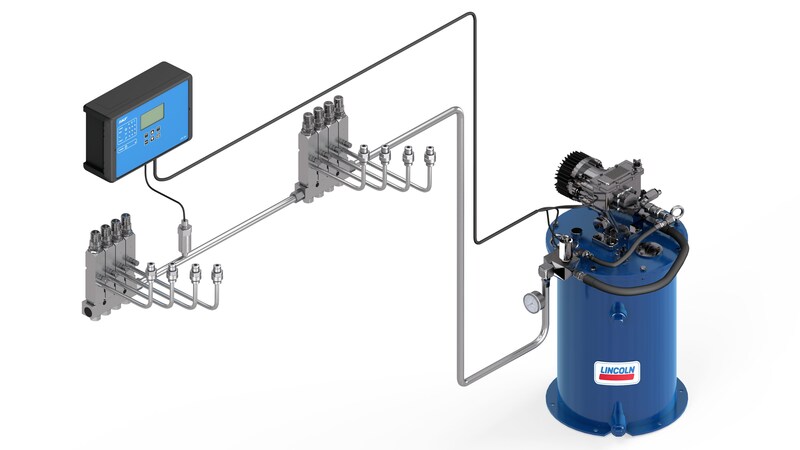

Single-line lubrication systems

for oil, fluid grease and grease

Regardless of the application, the principle of single-line lubrication remains the same: a central pump station automatically delivers lubricant through a single supply line to the lubricant metering device. Each metering device serves only one lubrication point and may be adjusted to deliver the precise amount of grease or oil required.

Systems can service one machine, different zones on one machine or even several separate machines.

The SKF portfolio includes both SKF MonoFlex and Lincoln Centro-Matic system components including pumps, metering units, control and monitoring devices and accessories. Depending on the lubricant (oil or grease) required for the application the system components differ in size and design.

Discover how SKF single-line lubrication systems work

Overview of single-line lubrication systems for oil, fluid-grease and grease

Benefits and applications

Easy and simpleto understand, install and maintain

suitable for almost all lubricants, available in both preset and adjustable models,Reliable

System continues to operate if one point becomes blockedEasy system expansion

able to pump long distances and within a wide temperature rangeVariety of applications

small-to-medium machine tools, mobile on-road (fleet vehicles, on-road transport), assembly/automation food packaging, part assembly lines, injection molding and more

Pumps

Metering devices

Monitoring devices

Control units