Oil levellers

Automatic adjustment for optimal lubricating oil level

How it works

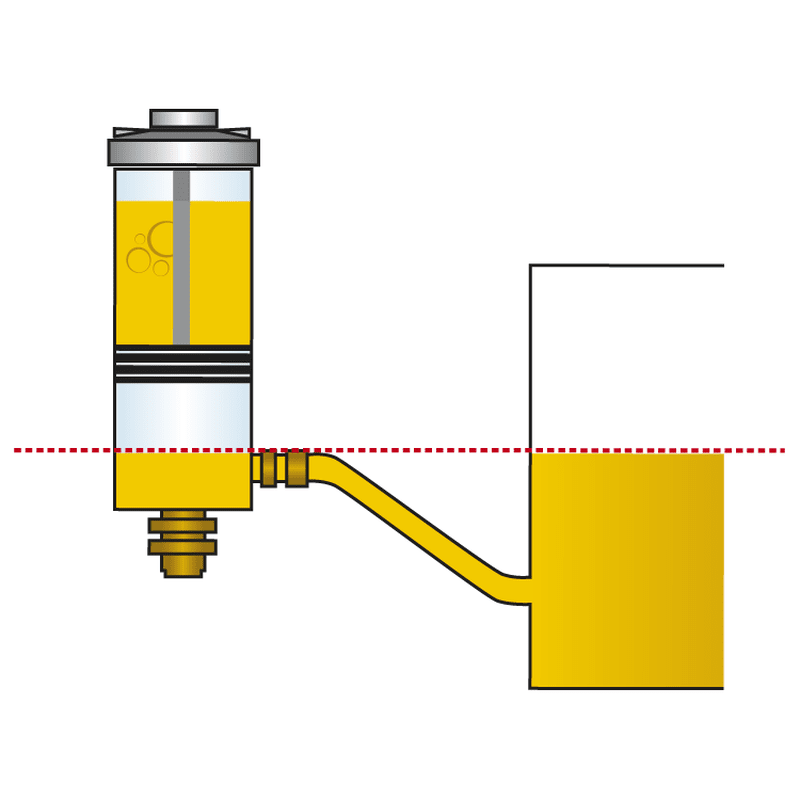

The SKF Oil Leveller consists of two communicating oil reservoirs. The lower reservoir is in direct contact with the application and hence its oil level is the same as the lubricating oil level inside the application. Through a ventilation tube, the lower reservoir is also in direct contact with the ambient air.

The upper reservoir is an airtight container storing replacement oil. Through its extended neck, which dips into the oil of the lower reservoir, the two reservoirs are in direct contact with each other. However, oil can only flow from the upper to the lower reservoir once the oil level in the lower reservoir goes below the pre-set level, allowing air to flow through the extended neck to the upper reservoir.

Optimally maintained oil level provides adequate lubrication

Easy visual inspection

Extended relubrication intervals. LAHD 1000 compensates for evaporation losses of up to 1 litre of lubricating oil!

Oil must be refilled manually

| Technical data | |

| Designation |

LAHD 500 / LAHD 1000 |

| Boundary dimensions |

|

| – LAHD 500 |

Ø 91 mm x 290 mm high (3.6 x 11.4 in.) |

| – LAHD 1000 |

Ø 122 mm x 290 mm high (4.8 x 11.4 in.) |

| Reservoir volume |

|

| – LAHD 500 |

500 ml (17 US fl. oz) |

| – LAHD 1000 |

1 000 ml (34 US fl. oz) |

| Container material |

Polycarbonate |

| Allowed temperature range |

– 20 to 70 °C (-4 to 158 °F) |

| Permissible humidity |

0 – 100 % |

| Length of connecting tube |

600 mm (23.5 in.) |

| Connection thread |

G 1/2 |

| Tube material |

Polyurethane |

| O-ring material |

NBR – 70 Shore |

| Gaskets |

NBR – 80 Shore 6 pieces |

| Other material |

Aluminum, Bronze, Stainless Steel |

| Suitable lubricating oil types |

Mineral and synthetic oils |