Neutron Chopper Drive Systems

The world’s leading neutron scattering facilities require unique and dependable instruments. These instruments must always be online to enable visiting scientists to make new material science discoveries

New payload design possibilities through higher speed rotation and increased bearing capacityContamination-free beam guides due to elimination of lubricantsHigher neutron flux densities at the sample with vacuum operation

Some of the prime benefits of SKF neutron chopper drive systems are:

High instrument reliability enabled by magnetic bearing technologyContact free rotation with no wear and minimal maintenanceFaster commissioning and simplified monitoring of system health using MBScope and SKF @ptitude Observer software tools Validated to ISO standards for machine vibration and stability

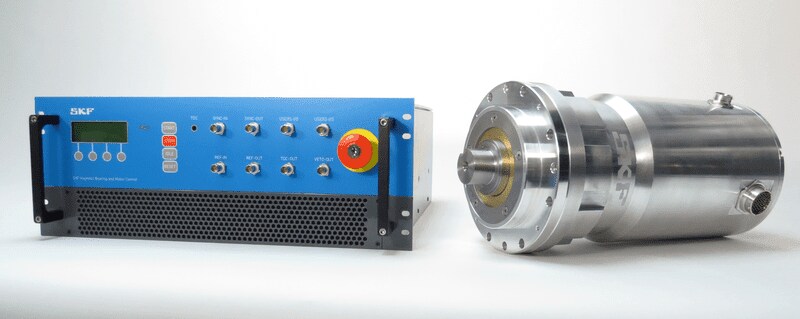

An SKF neutron chopper drive system is a plug and play solution that includes a controller, spindle, and cabling.

Magnetic Bearing Controller

The controller is responsible for both the magnetic bearings and the motor control. It provides precise phase control and communicates with the instrument’s master control system. SKF’s latest offering is built upon our 5th generation technology which has been refined across multiple industries.

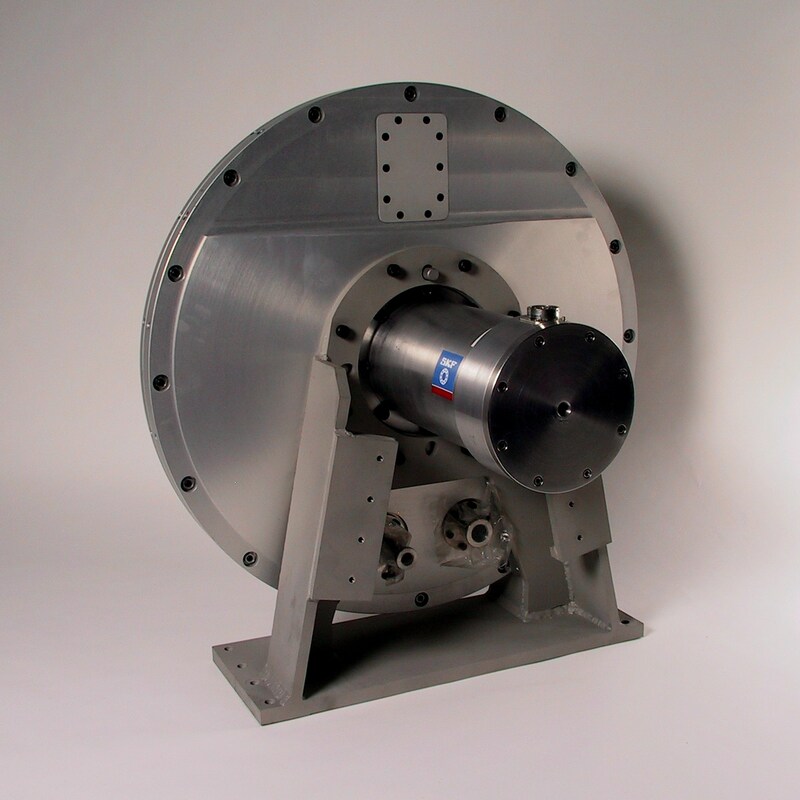

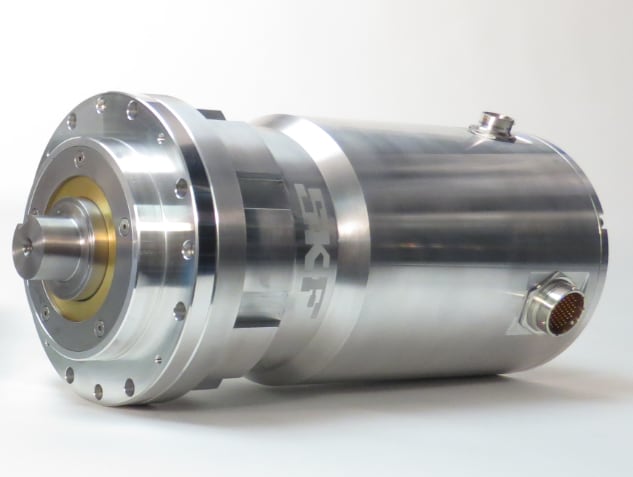

Spindle

SKF offers a number of spindle types for neutron choppers including disk, Fermi, and T0 – all designed to be compatible with a wide range of payloads. SKF works with neutron facilities and payload providers to integrate mechanical, electronic, and communication systems.